Consider everything – implement the best

Improving on products and procedures that are already accepted as good, finding new ideas and implementing them is the passion of API. Twenty years ago, only 2% of an building was made of plastic and plastic related products. Nowadays, this percentage has increase to more than 30% in special cases and API is actively contributing to shape the future of plastic engineering.

Since the company was first established, research and development have been one of our focuses, just like our quest for the continued improvement of products and processes.

Saver more efficient and Eco-friendly

Saver more efficient and Eco-friendly

These are key targets of any research project at API. In each of the following fields, we employ experts striving to replace metal components with innovative plastics or composite structures and to upgrade and refine existing design concepts. Our main competences and specializations include:

Development of Manufacturing process

Our aim is to establish new processes for serial production in our organization. In this endeavor, the increase of the degree of automatio n and of production quantities, combined with an improvement in production quality features as a key parameters. Examples include new liquid resin infusion processes, or automated tool an workpiece change that automates the manual placement on the processing machines.

n and of production quantities, combined with an improvement in production quality features as a key parameters. Examples include new liquid resin infusion processes, or automated tool an workpiece change that automates the manual placement on the processing machines.

Prototype development

At this stage, various design concepts for a component are elaborated and assessed. According to the resulting list of priorities, the best concepts are developed int prototypes. These are then subjected to an intensive testing regime which includes the use of realistic conditions.

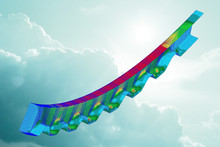

Simulation

Components as well as manufacturing processes are simulated based on the finite element method (FEM). For components, (e.g.structural parts), justifications such as strength, stability and fatigue are performed in order to ensure their subsequent safe use in all conditions. Manufacturing process are simulated to achieve optimum component quality.

Material characterization

The specialist in this field analyze the latest developments of materials research as to their suitability for use at API. They examine whether the material meet the specific requirements of the plastic industry and whether they can be adapted to the manufacturing processes in use at API.

-1222.png )