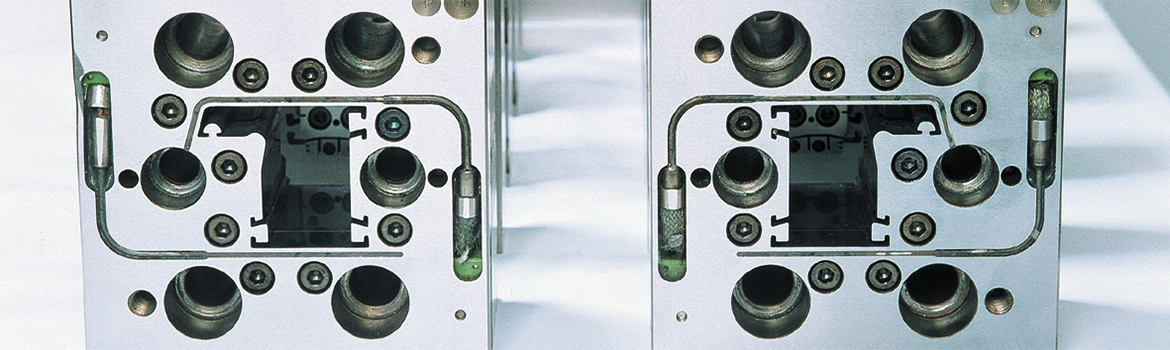

High End Extrusion Dies

Segmented Dies from Austroplast are currently state of the art and world wide accepted for their accuracy and cost saving effects in the production of extruded profiles. Having been developed to improve process stability, Semented Dies retain the sturdiness of Mandrel Dies while allowing for improve precision in guidance of melt flows. A larger production window makes this tooling system ideal for complex profile geometries, co-extrusion and processing of regrind.

Quality and Stability

Close and intensive cooperation with European steel manufacturers leads to the well-known first class Austroplast Tool Steel Quality. Together with rigid quality control and latest development all of these efforts lead to improved wear resistance and elongate of lifespan for our tools. Whenever possible, we use standardized modular elements to reduce spare part logistic.

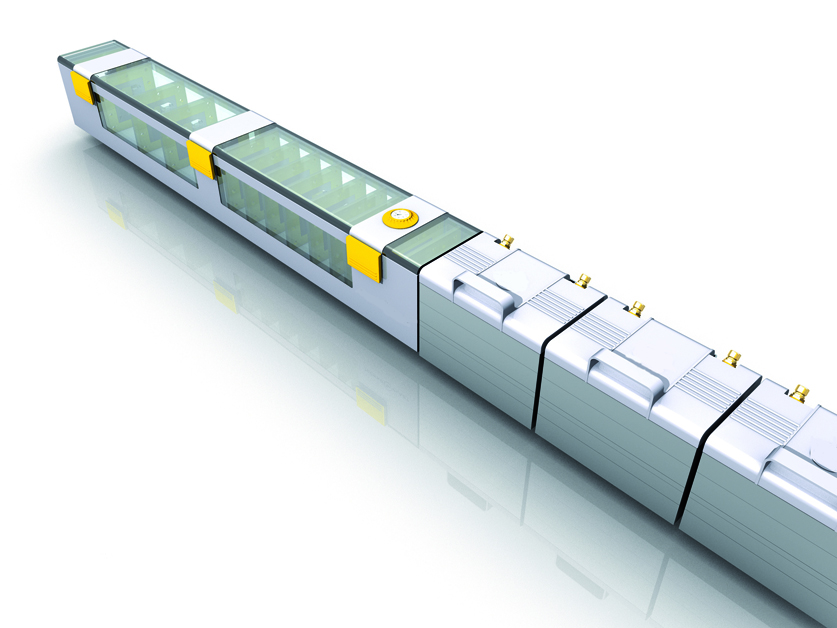

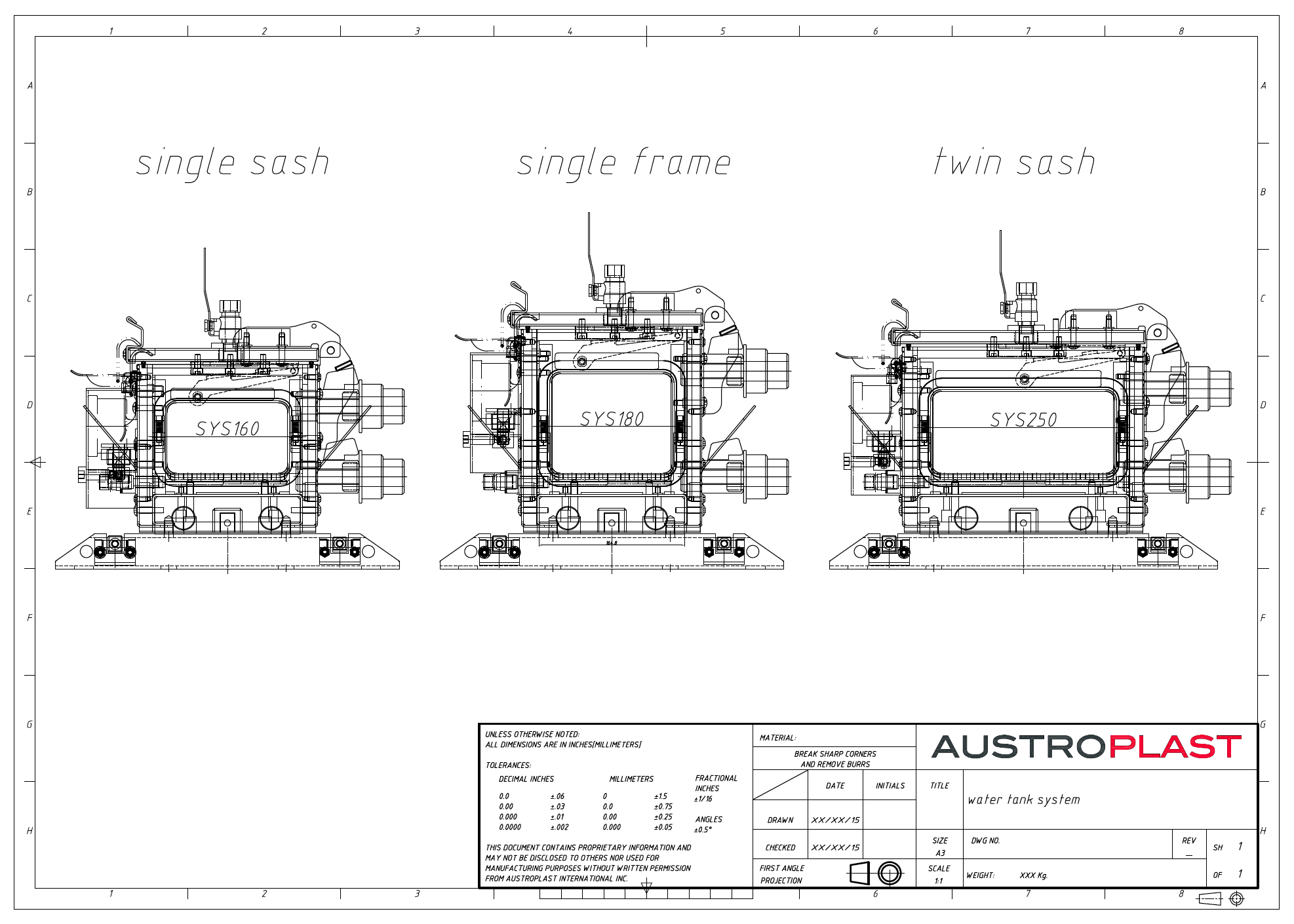

Dry Calibration

The dry calibrator keeps the 200 degree hot PVC coming form the die in the form and cools it down at surface nearly to room temperature. Central water and vacuum connections and a well positioned fastening system allow tool-less changing of calibrators in a short period of time.

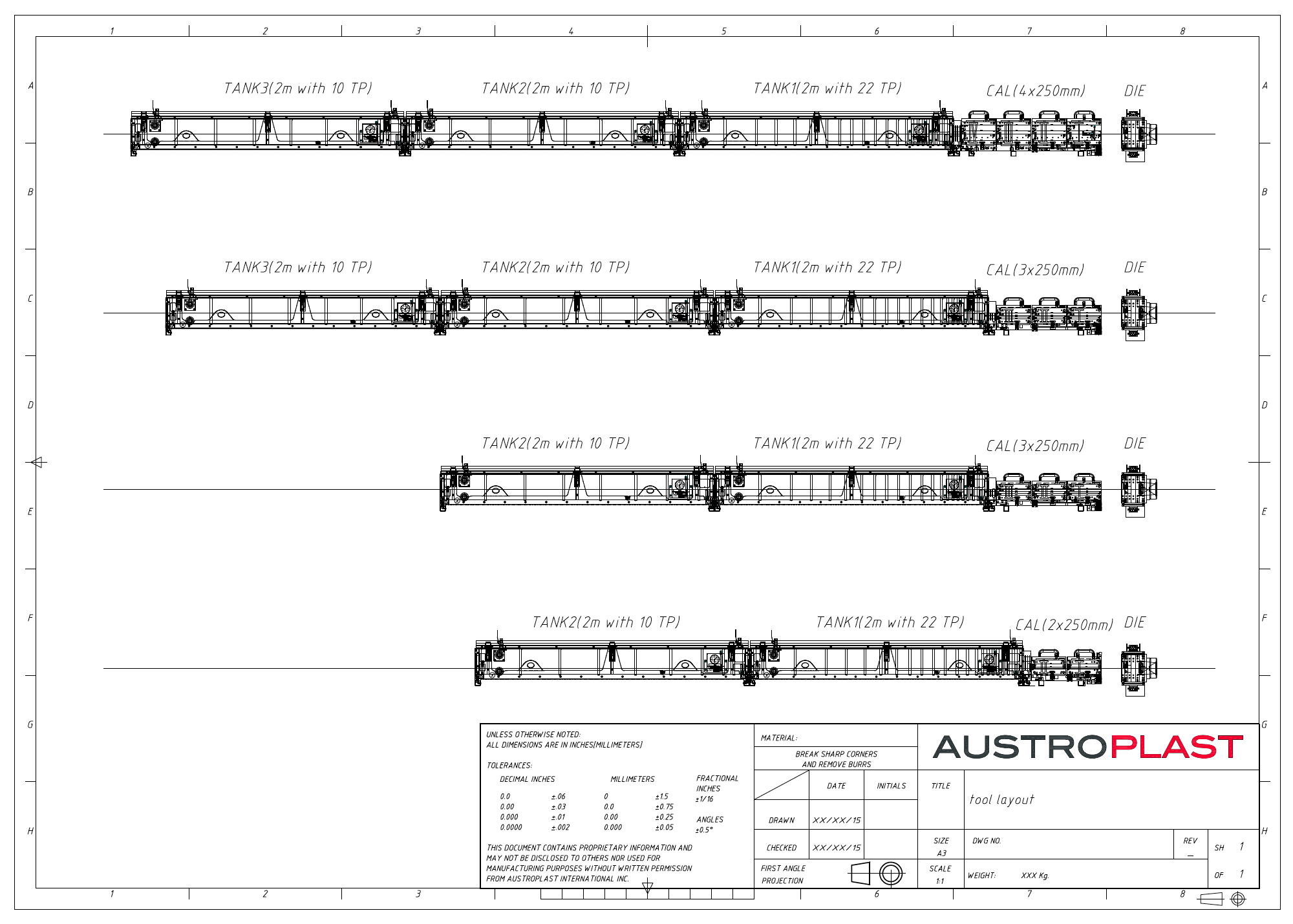

Wet Calibration

We use our world wide patented whirl-bath technology for the highest cooling with the lowest water consumption. Standardized sized of tanks are interchangeable with different profiles.

-1222.png )